The core task of an air-cooled condenser is to efficiently condense the high-temperature exhaust steam discharged after the turbine has completed its work into water, thereby establishing and maintaining a vacuum at the exhaust outlet, which is crucial for improving the efficiency of the entire thermal cycle.

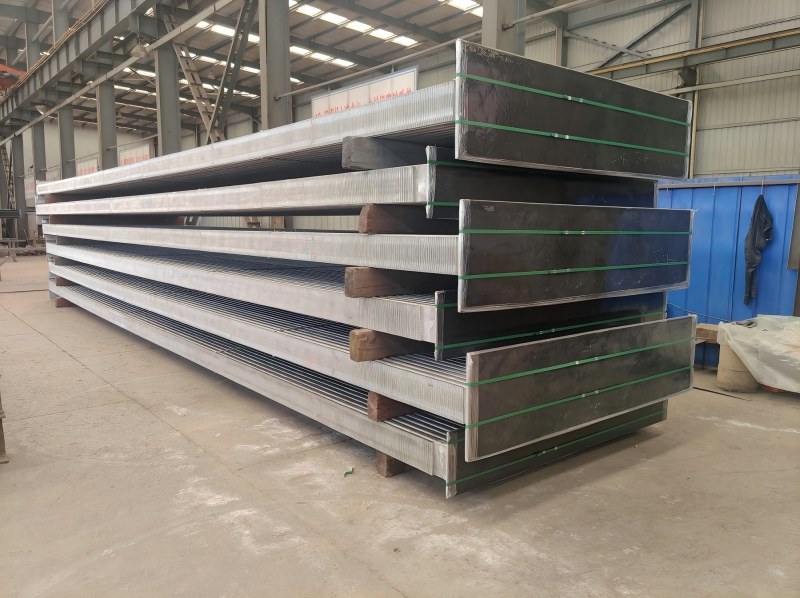

Direct air cooling system: The exhaust steam of the steam turbine is directly led to the air-cooled condenser tube bundle arranged outside the plant and supported by the A-frame through a large-diameter pipeline. When these exhaust gases flow inside the bundle, the large-diameter axial flow fan at the bottom of the bundle will forcefully blow air, causing cold air to sweep over from outside the bundle. Steam releases latent heat of vaporization and condenses into water, which flows into the condensate tank and is pumped back to the boiler for recycling. The non-condensable gas is discharged by the vacuum system to maintain the vacuum degree of the system.

Indirect air cooling system: The exhausted steam after work is first transferred to the circulating cooling water in a hybrid or surface condenser. The heated cooling water is then sent to the aluminum tube and aluminum fin radiators (forming a "cooling triangle") around the natural ventilation cooling tower through a circulating pump. Under the natural suction force of the cooling tower, ambient air sweeps across the finned tubes of the radiator, taking away heat and cooling the cooling water before returning to the condenser for further circulation.

As the core heat exchange element of a direct air-cooled condenser, the working mode of a single row tube can be understood as follows:

Heat exchange process: The high-temperature exhaust steam discharged from the turbine enters the single exhaust pipe through a large-diameter steam distribution pipe. At the same time, the large-diameter axial flow fan at the bottom of the device forcefully blows air, causing ambient cold air to sweep through the outside of the tube bundle. The steam inside the tube releases heat and condenses into water, which is then transferred to the air through the tube wall and fins.

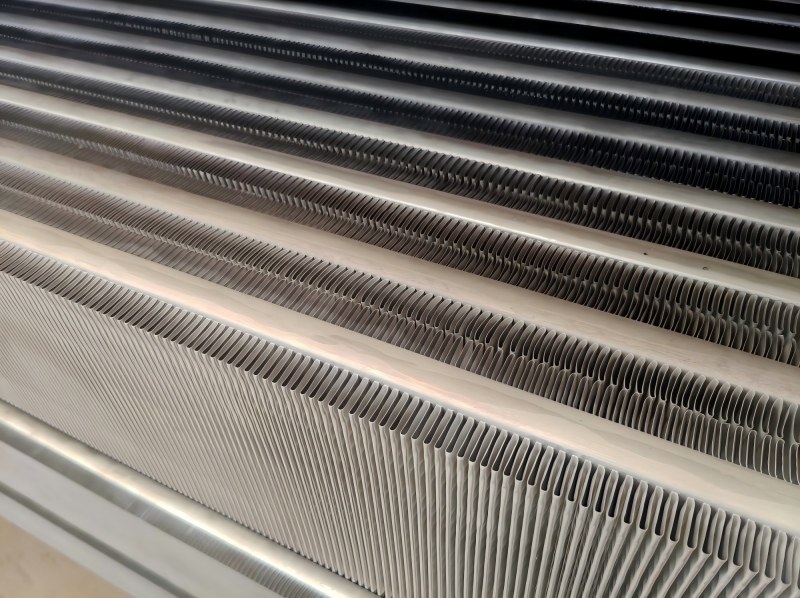

Structural design and performance: The single row tube adopts a large-diameter base tube and a flattened shape design, and is then brazed with fins to form a large-diameter flat serpentine brazed finned tube. This unique structure, combined with serpentine flow channels, can effectively increase the heat transfer area, promote fluid turbulence, and enhance heat transfer. Research has shown that by conducting three-dimensional numerical simulations of airflow and heat transfer on the air side, it is possible to derive calculation formulas for the variation of tube bundle resistance and heat transfer coefficient with face wind speed, providing an important basis for the optimization design of air cooling systems.

When the core of your process involves condensing steam into liquid and establishing and maintaining a vacuum, an air-cooled condenser must be used instead of a regular process air cooler. This mainly occurs in the following scenarios:

Steam turbine exhaust condensation in thermal power plants or nuclear power plants (the most important and typical application)

Core function: In the Rankine cycle, the air-cooled condenser is used to condense the low-pressure steam (exhaust steam) discharged after the turbine has completed its work, turning it back into water (condensate), thereby establishing and maintaining a high vacuum at the exhaust end of the turbine. Vacuum degree is one of the key factors determining the power generation efficiency of a unit.

Why is it necessary to use: Only by condensing steam to generate an extremely high vacuum can the expansion and work capacity of steam in the turbine be maximized, thereby significantly improving the thermal efficiency of the entire power plant.