If you have any questions or Suggestions about our products or services, please feel free to contact us at any time! Our technical engineers will give you detailed answers.

Parts

|

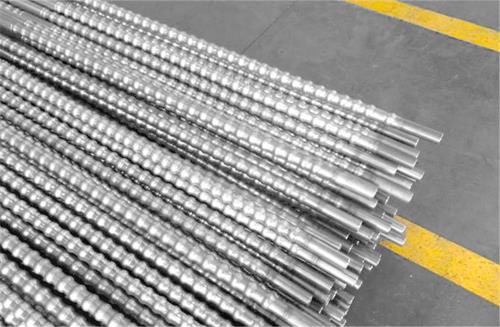

Corrugated tube Corrugated tube has many spiral projections on the inner and outer surface of the tube. The coefficient for overall heat transfer has been remarkably improved because of the turbulent flow effect on the inner surface and outer surface of the tube caused by the corrugation |

|

|

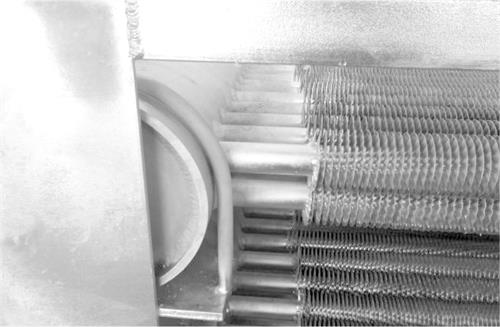

Finned tube The finned tube is the main heat exchange element of the air cooler, and its structure directly determines the performance of the entire heat exchanger. At the same time, the connection between the fin and the base tube also has a great influence on the heat transfer. The fin is mainly made of aluminum, steel or hot-dip galvanized steel. |

|

|

Axial Fan Axial flow fan adopts hollow aluminum alloy impeller (standard configuration) dedicated for evaporation and condensation, with forward-tilted structure design of the blade, low wind resistance, large air volume, low noise, good performance, high efficiency, and direct connection, reducing transmission Components, the motor uses a fully enclosed self-cooled motor, protection grade IP55, the shell is sprayed with static electricity, acid and alkali resistance, corrosion resistance. |

|

|

PVC filling The filler is made of PVC fireproof material and is fish-shaped. Spray water can evenly distribute the entire packing area to improve heat transfer performance. |

|

|

Dry fin cooling coil Copper tube structure with aluminum fins can improve cooling capacity and reduce or eliminate white mist |

|

|

Condensation coil The condensing coil is the key part of the unit. In order to improve the heat transfer coefficient inside and outside the tube, the condensing coil adopts elliptical high conductivity tube or circular internal and external thread high-efficiency heat exchange tube and through the overall high-temperature hot-dip zinc at 487 ℃, to ensure the overall anti-corrosion ability. The design pressure of the coil is 2.0MPa. After three of pressure test (2.5MPa) and the last 24 hours of pressure maintenance, the air tightness and strength of the coil are guaranteed. |

|

|

Circulating water pump The circulating water pump adopts a large flow, low head, low power evaporative cooling special pump, and the shaft seal adopts a special mechanical seal ring produced by German forced circulation without restriction of steering, without leakage and long life. |

|

|

Drift Eliminator Drift eliminators are designed to control the loss of drift droplets that evaporate into the atmosphere in a cooling tower by capturing and preventing the harmful droplets from exiting the cooling tower and into the environment. Drift eliminators perform their function by causing droplets to switch direction and lose their velocity once they hit the blade walls causing the droplets to fall back into the cooling tower. The most efficient cooling tower drift eliminators will keep your loss of drift to lower than 0 .001% drift rate. |

|